Hey everyone, it’s Oscar from Side Hustle Playbook! Sundays are always a great time to catch up on side hustle tasks, and this past one was no exception. From printing shirts to tackling sublimation tumblers, it was a productive day full of lessons and even a few challenges. Here’s a behind-the-scenes look at my journey.

Sublimation Tumbler Experimentation

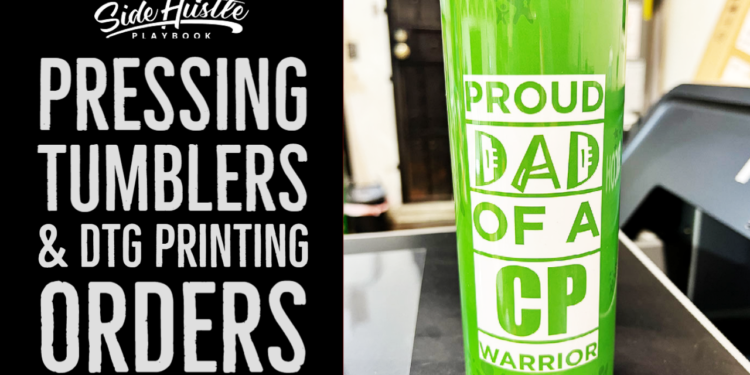

I’ve been making some progress with sublimation, focusing primarily on mugs, but this time I decided to tackle skinny tumblers using my mug/skinny tumbler heat press. My first attempt? Let’s just say it didn’t go as planned. Ghosting issues plagued the final product, mostly due to a rushed taping job.

Determined to improve, I approached this second attempt with more care. I taped the design down securely, added blowout paper to avoid transferring any stray ink onto the press, and followed a precise heating schedule: 365°F for 60 seconds, rotated 180 degrees, and heated for another 30 seconds. The result? A big improvement, though I’m still working on perfecting the edges around the top and bottom of the tumbler.

Lessons Learned from Sublimation

- Taping Technique Matters: Pull the paper tightly as you apply the tape, and don’t rush. Precision is key to avoiding ghosting and ensuring a seamless design.

- Experiment with Edges: Techniques like folding excess paper over the top or bottom can help, but it’s all about finding what works best for you.

- Practice Makes Perfect: It’s all trial and error. Each attempt gets you closer to the level of quality you’re aiming for.

While the tumblers aren’t quite ready to sell yet, I’m excited about the progress I’ve made and can’t wait to keep refining my process.

Dealing with Equipment Issues

No side hustle is without its challenges, and mine came in the form of my trusty conveyor dryer. This piece of equipment has been a workhorse for curing shirts, but on this particular day, the exhaust fan refused to start. Power wasn’t the issue, and after some troubleshooting, it became clear that the fan itself might need replacement.

In the meantime, I relied on my heat press to get the most urgent shirt orders cured and ready to ship. While slower, having a backup plan saved the day and ensured no customer was left waiting.

Why Backup Plans Matter

This experience was a reminder of how crucial it is to have contingency plans. For my print-on-demand business, here’s what’s been working:

- Heat Press as a Backup: Slower, but reliable for curing shirts when the dryer is out of commission.

- Print-on-Demand Services: Platforms like Printify provide a lifeline for fulfilling orders during high-demand periods or equipment downtime.

- Regular Maintenance: Stay on top of routine cleaning and inspections to minimize unexpected breakdowns.

Looking Ahead

Despite the hiccups, I’m feeling good about the day’s accomplishments. The tumbler experiment was a step forward, and I’m confident that with more practice, I’ll be ready to offer them to customers soon. As for the dryer, I’m working with support to diagnose and resolve the issue, and I’ll be sure to keep you all updated.

This journey is a great example of the ups and downs that come with running a side hustle. The key is to stay flexible, keep learning, and always have a plan B. Thanks for following along, and if you’re building your own side hustle, I’d love to hear about your experiences in the comments!

Stay Connected

Until next time, keep hustling and growing your dreams!